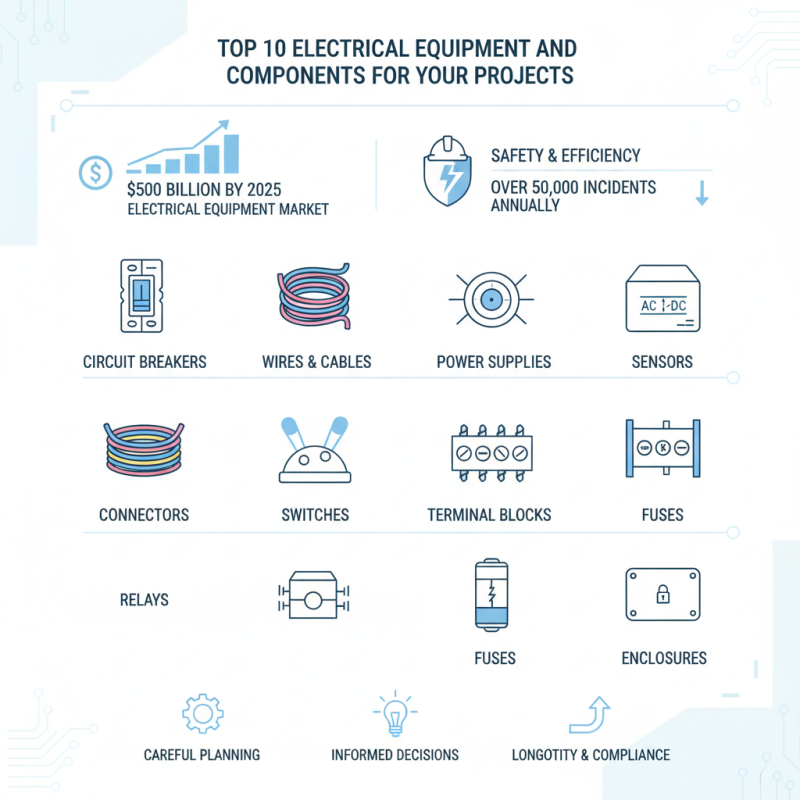

In today's fast-paced technological environment, the right electrical equipment and components are essential for project success. According to a recent report by the International Electrotechnical Commission, the electrical equipment market is expected to reach $500 billion by 2025. This statistic highlights the growing demand for quality electrical components in various industries, including construction, automotive, and renewable energy.

Choosing the right electrical equipment is not just about performance; it's also about safety and efficiency. In 2022, the U.S. Electrical Safety Foundation International reported over 50,000 electrical-related incidents annually, stressing the importance of using reliable components. Architects and engineers must prioritize quality while being conscious of budgets and timelines. This dual focus ensures projects not only meet deadlines but also uphold safety regulations.

Many professionals overlook certain components, thinking they are merely optional. However, investing in high-quality connectors, switches, and circuit protection devices can prevent costly delays later. Electrical equipment and components are the backbone of any project. They require careful planning, informed decisions, and ongoing evaluation to ensure longevity and compliance.

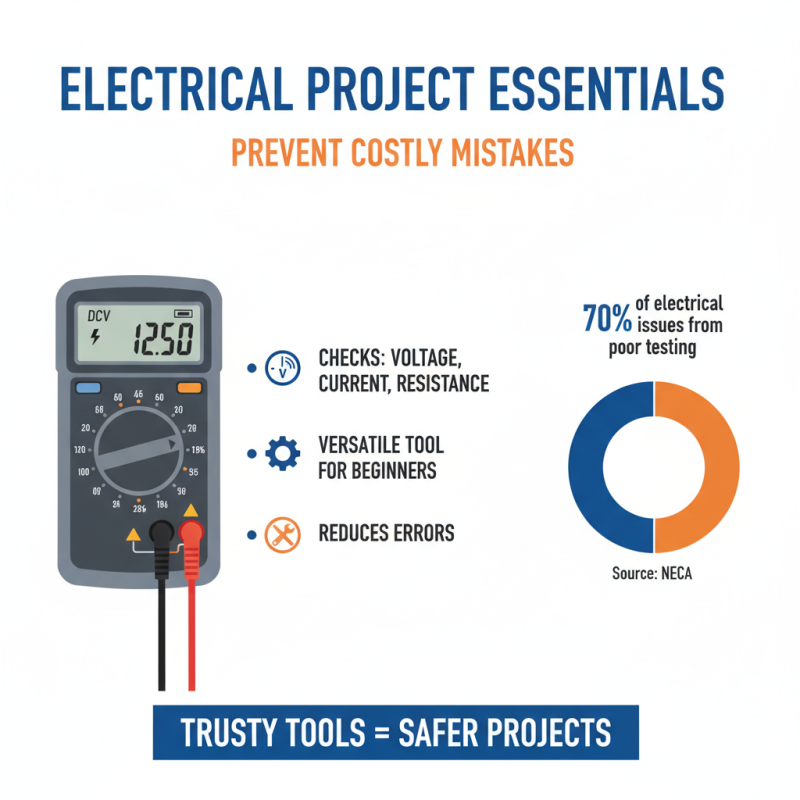

When starting any electrical project, having the right tools is crucial. A multimeter is essential. It checks voltage, current, and resistance, making it a versatile tool for beginners. According to the National Electrical Contractors Association, nearly 70% of electrical issues stem from poor testing methods. This highlights the need for reliable tools that can prevent costly mistakes.

Wire strippers come next. They simplify the process of preparing wires. Properly stripped wires ensure good connections, reducing the risk of shorts or outages. Without this tool, beginners might struggle and produce unreliable setups. In fact, industry reports indicate that improper wire connections cause around 30% of electrical system failures.

Another key component is a soldering iron. This tool creates strong and permanent joints. Many novices often rush this step, leading to weak connections. Research indicates that nearly 20% of electrical fires are linked to faulty soldering. Carefully mastering this technique is essential for safe and effective project execution.

A quality toolset lays the groundwork for successful project development. Missing one simple tool can derail progress. Investing time to learn about these tools will significantly enhance a beginner’s confidence and skills.

When starting electrical projects, it's crucial to understand the types of components you'll need. Resistors, for instance, limit current flow in circuits. They're available in various resistance values. Selecting the right resistor can be tricky. Too high or too low can affect your circuit’s performance.

Capacitors store energy. They release it when needed. Different types, such as electrolytic or ceramic, serve unique purposes. Keep in mind the voltage rating and capacitance. Misjudging these can lead to circuit failure.

Switches allow control over the flow of electricity. They come in many forms. Toggle, push-button, or slide are common types. Each has its advantages and applications. An incorrect switch choice can disrupt your project. Planning is essential, but experimentation often leads to learning. You may feel lost at times, but that's part of the journey.

| Component | Type | Function | Common Use |

|---|---|---|---|

| Resistor | Passive | Limits current flow | Voltage dividers, biasing |

| Capacitor | Passive | Stores electrical energy | Filtering, timing circuits |

| Inductor | Passive | Stores energy in a magnetic field | Filters, oscillators |

| Diode | Active | Allows current to flow in one direction | Rectification, protection circuits |

| Transistor | Active | Amplifies or switches electronic signals | Signal amplification, digital circuits |

| Transformer | Passive | Transfers electrical energy between circuits | Voltage conversion, isolation |

| Relay | Electromechanical | Electrically operated switch | Automation systems, control circuits |

| Microcontroller | Active | Programmable control functionality | Embedded systems, robotics |

| Breadboard | Tool | Prototyping circuit layouts | Testing and experimentation |

| Power Supply | Component | Provides usable electrical power | Electronic devices, circuits |

When working with electrical projects, safety gear is crucial. According to the National Safety Council, improper handling of electrical equipment accounts for thousands of workplace injuries annually. It’s essential to have the right equipment to minimize risks. Basic items include insulated gloves and safety goggles. These can protect against electrical shocks and flying debris.

Wearing rubber-soled shoes is another vital precaution. They help prevent electrical accidents on damp surfaces. Also, using a reliable voltage tester ensures circuits are live-free before work begins. The Occupational Safety and Health Administration (OSHA) emphasizes that using personal protective equipment (PPE) reduces risk significantly.

However, many overlook the importance of regular gear inspections. Worn-out gloves or damaged goggles can provide a false sense of security. In fact, reports indicate that 30% of electrical injuries result from improper equipment usage. Regular training and refreshers on safety best practices also play a role in maintaining safety standards. Ultimately, ensuring safety gear is in top condition is a key factor in reducing workplace hazards.

When selecting electrical equipment for projects, several critical factors must be considered. First, it is important to assess the specific requirements of your project. For instance, power capacity, voltage levels, and location constraints can greatly influence your choice. Research indicates that 72% of project failures are linked to equipment mismatches or poor specifications. Carefully defining these parameters upfront can mitigate risks.

Tips: Always create a detailed project specification sheet. Include all necessary voltage ratings and load capacities. This will help guide your equipment choice.

Compatibility is another key consideration. Ensuring that components work well together can prevent operational issues. According to industry standards, improperly matched equipment can lead to inefficiencies of up to 30%. Focus on integration when selecting parts.

Tips: Check compatibility with existing systems. Collaboration with suppliers can provide insights into common pitfalls. Avoid overlooking this step as it can save time and money.

Lastly, consider the long-term maintenance and availability of replacement parts. Choosing equipment with readily available components can enhance your project's sustainability. Reports show that 64% of maintenance issues arise from outdated components. Regular updates and replacements are crucial for a smooth operation.

Maintaining and storing electrical tools is crucial for longevity and safety. Keep tools in a clean, dry space. Moisture can lead to rust and malfunction. Use labeled containers for small components. This prevents loss and mix-ups. Organize everything for easy access.

Regularly inspect tools for wear and tear. Tighten loose parts and replace worn-out items. This not only ensures safety but also improves efficiency. Using damaged tools can lead to mistakes. Reflect on your usage patterns. Are you storing everything properly?

Avoid overcrowding your storage area. A cluttered space can make finding tools challenging and unsafe. Consider using pegboards for easy visibility. While it may take time to organize, the benefits pay off. Your projects will run smoother. A well-maintained toolkit inspires confidence in your work.