In the ever-evolving world of electronics, the efficiency and precision of printed circuit board (PCB) manufacturing and assembly are crucial to the success of various applications, from consumer electronics to industrial machinery. The backbone of this process lies in the circuit board equipment utilized during production. Selecting the right tools and machines is essential for manufacturers aiming to stay competitive in a fast-paced market.

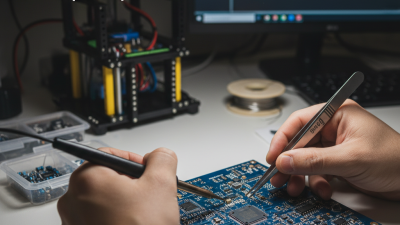

Modern circuit board equipment has transformed traditional PCB manufacturing into a highly automated and streamlined process. Innovations in technology not only enhance the speed and quality of production but also minimize waste and reduce the overall cost of manufacturing. From soldering techniques to inspection systems, the array of available equipment plays a significant role in ensuring that the final product meets the highest standards of performance and reliability.

As the demand for more complex and efficient circuit boards increases, understanding the latest advancements in circuit board equipment becomes imperative for manufacturers seeking to optimize their production lines. This article will explore the top circuit board equipment available today, highlighting their features and benefits, and demonstrating how they can significantly improve PCB manufacturing and assembly processes.

The efficient manufacturing and assembly of printed circuit boards (PCBs) hinge on the integration of advanced circuit board equipment. With the global PCB market projected to reach approximately $100 billion by 2026, a clear understanding of the essential equipment is critical for businesses aiming to optimize production. Key equipment includes automated optical inspection (AOI) systems, which play a crucial role in quality control by detecting defects in the early stages of assembly. According to recent industry reports, implementing AOI can reduce assembly errors by up to 70%, significantly enhancing overall product quality.

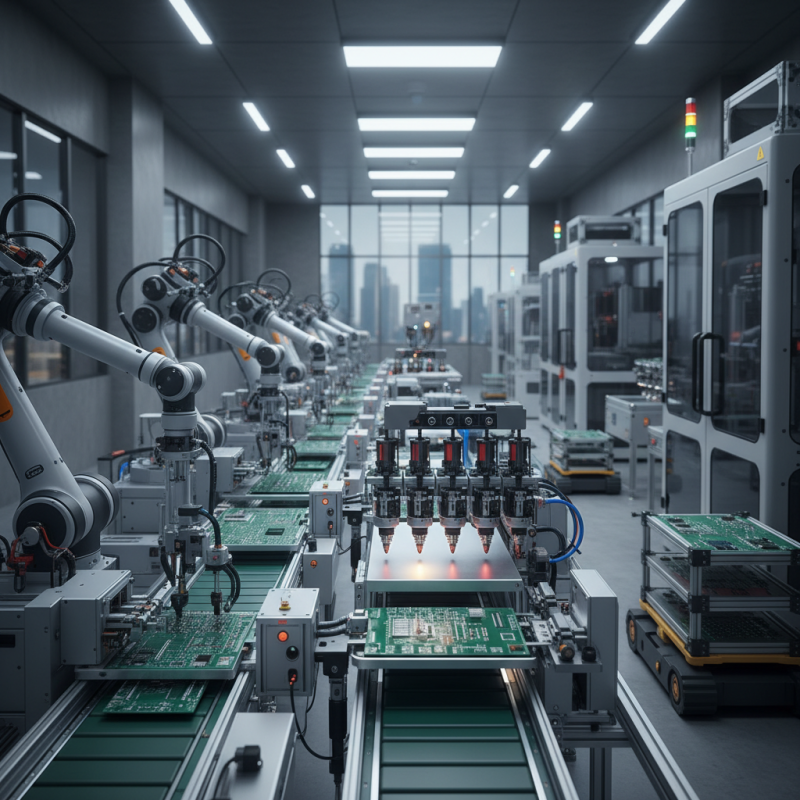

Additionally, advancements in pick-and-place machines have revolutionized the assembly process. These machines can place thousands of components per hour, boasting accuracy rates of over 99.5%. As a result, manufacturers are able to increase throughput without compromising on precision. A study from a leading electronics industry analysis firm indicates that investing in high-speed pick-and-place technology can lead to a 30% reduction in production time, enabling companies to meet growing consumer demand more efficiently. As the industry continues to evolve, leveraging these cutting-edge tools will be essential for maintaining competitiveness in the PCB manufacturing landscape.

In the ever-evolving landscape of electronics, efficient PCB manufacturing and assembly hinge on advanced technologies that streamline the production process. One of the key technologies leading the way is automation, which minimizes human error and increases output. Automated optical inspection (AOI) systems are critical for ensuring quality control, scanning circuit boards for defects in real-time. This technology helps speed up the assembly process, allowing manufacturers to maintain high standards while keeping pace with market demand.

Another essential component in modern PCB manufacturing is the use of advanced laser systems. These lasers can perform precision cutting and drilling with remarkable accuracy, resulting in intricate designs that were once difficult to achieve. Additionally, laser technology facilitates quick prototyping, enabling faster turnaround times for new product designs. Manufacturers who leverage laser technology often find that their ability to innovate increases significantly, allowing them to stay competitive.

Tips: When integrating new technologies into your PCB manufacturing process, consider conducting a trial run to evaluate the compatibility and efficiency of the equipment. Moreover, investing in employee training can enhance productivity significantly, as skilled operators can better navigate the complexities of advanced machinery. Always prioritize quality assurance assessments to maintain industry standards and ensure customer satisfaction.

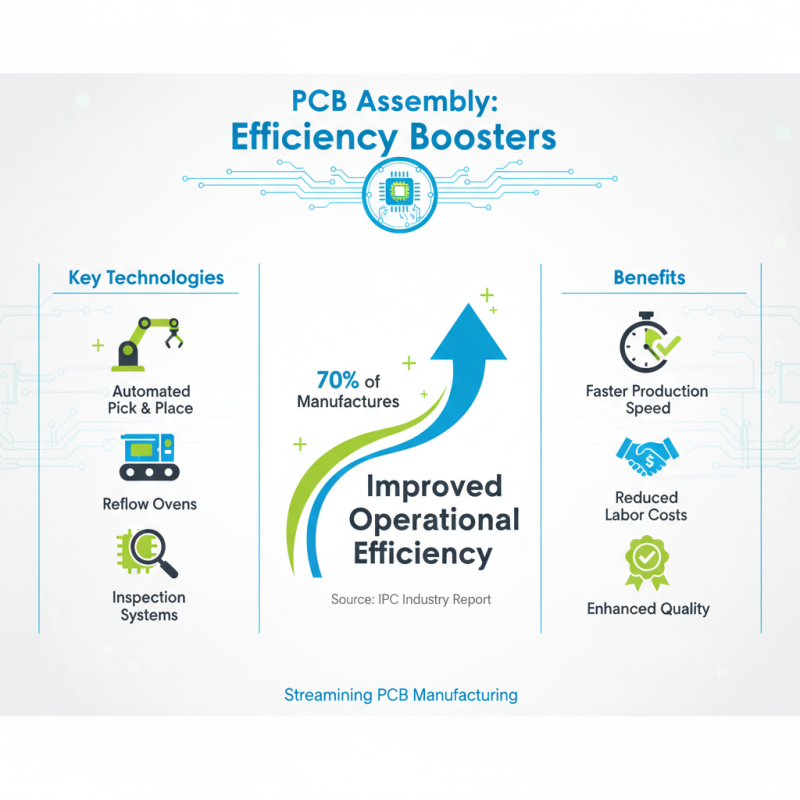

In the realm of Printed Circuit Board (PCB) manufacturing, efficiency is paramount. Essential tools for PCB assembly significantly influence production speed and quality. According to a recent industry report by IPC, nearly 70% of manufacturers cite the adoption of advanced assembly technologies as a key factor in improving their operational efficiency. These technologies include automated pick-and-place machines, reflow ovens, and inspection systems, which collectively streamline the assembly process while reducing labor costs.

One of the most impactful tools in PCB assembly is the automated pick-and-place machine, which facilitates the rapid placement of components onto circuit boards. Studies show that these machines can enhance placement accuracy to over 99%, increasing the reliability of the final product. Coupled with advanced software solutions for inventory and workflow management, manufacturers can achieve unprecedented levels of speed and efficiency. Moreover, implementing automated optical inspection (AOI) systems helps ensure quality control, reducing the rate of defects significantly—by as much as 30%, as reported by industry analysts.

Furthermore, the integration of Industry 4.0 technologies into PCB manufacturing is reshaping assembly processes. By utilizing the Internet of Things (IoT) and data analytics, manufacturers can monitor production in real time, identifying bottlenecks and optimizing workflows. Research indicates that companies that have embraced these smart manufacturing practices report a 20-40% increase in productivity. As the industry evolves, the emphasis on efficiency will remain crucial, making the right tools for PCB assembly even more essential for sustaining competitive advantage.

Innovations in circuit board production are transforming the landscape of PCB manufacturing and assembly. One of the most notable advancements is the adoption of automated processes and advanced machinery, which significantly enhance production efficiency. According to a report by IPC, the global PCB market is expected to reach $82 billion by 2025, driven by the growing demand for consumer electronics and increasingly complex circuit designs. This surge is pushing manufacturers to rely on cutting-edge equipment that can accommodate rapid production rates while maintaining high levels of precision.

Furthermore, the integration of smart manufacturing technologies, such as IoT and AI, is revolutionizing quality control and process optimization in PCB production. For instance, predictive maintenance using AI algorithms helps in reducing downtime by anticipating equipment failures before they occur. A study from the McKinsey Global Institute indicates that automation and advanced manufacturing practices could potentially increase productivity by up to 30% in the electronics industry. These innovations not only enhance efficiency but also facilitate the development of highly intricate designs essential for modern electronic applications, positioning manufacturers to meet the escalating demands of the market effectively.

When selecting equipment for PCB manufacturing and assembly, several best practices can enhance efficiency and reliability. First, it’s crucial to conduct a thorough needs assessment to identify the specific requirements of your production line. Understanding the types of PCBs you intend to manufacture—whether rigid, flexible, or multi-layer—will guide your equipment selection. Reports indicate that the global PCB market is projected to reach USD 80 billion by 2025, driven by increased demand from sectors like automotive and electronics. Adapting your equipment strategies to meet evolving industry standards can ensure that you remain competitive.

Another essential consideration is the compatibility of equipment with automated solutions. Automation can significantly reduce manufacturing times and increase precision, often improving the accuracy of placements by up to 99%. Incorporating advanced technologies such as laser direct imaging and automated optical inspection can help identify defects early in the process, streamlining assembly and reducing waste.

Tip: Always invest in training for your staff on new equipment and technologies. Properly trained operators can maximize the capabilities of the machinery, leading to enhanced productivity and reduced downtime. Staying updated with industry trends through professional seminars and workshops can also aid in making informed decisions regarding equipment investments.

| Equipment Type | Function | Key Features | Considerations |

|---|---|---|---|

| Automatic Pick and Place Machine | Assembly of SMT components | High speed, accuracy, multiple feeder slots | Cost, setup time, programming complexity |

| Reflow Oven | Soldering of SMT components | Temperature zones, conveyor belt | Energy consumption, footprint, maintenance |

| Screen Printer | Applying solder paste | Precision, adjustable squeegees | Setup time, substrate placement accuracy |

| Inspection System (AOI) | Quality control of assembled boards | Image processing, real-time feedback | Integration with production line, cost |

| Wave Soldering Machine | Through-hole soldering | Variable speed, adjustable wave height | Setup complexity, maintenance |