In today's fast-paced technological landscape, the choice of equipment cords has become increasingly crucial for both efficiency and safety. According to a recent industry report by the Electronics Industry Association, improper cord selection can lead to a staggering 30% increase in energy consumption and potential safety hazards. With the demand for high-quality, reliable power solutions growing, understanding the nuances of equipment cords is essential for anyone looking to optimize their operational capabilities.

Moreover, the National Electrical Manufacturers Association indicates that the global market for power cords is projected to reach $13 billion by 2025, emphasizing the importance of choosing the right cords that not only meet performance standards but also align with specific operational needs. Whether for industrial machinery, office setups, or home electronics, the right equipment cords can significantly enhance the longevity and effectiveness of your devices. Therefore, this guide will provide top tips for selecting the best equipment cords tailored to your unique requirements, ensuring that you make informed decisions based on expert insights and industry data.

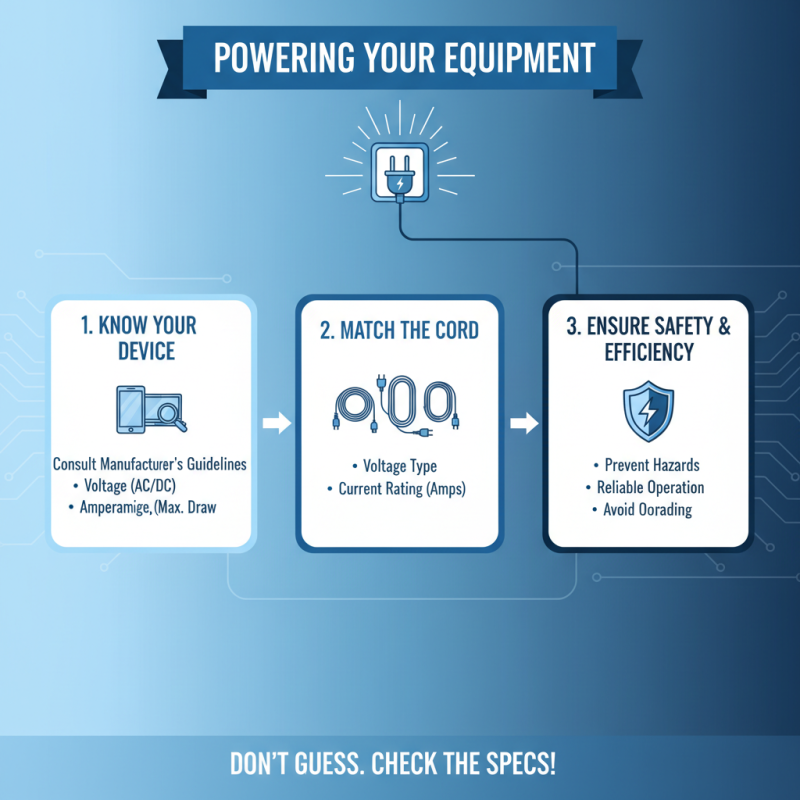

When it comes to choosing the best equipment cords, understanding your equipment's power requirements is paramount. Each device has specific voltage and amperage specifications that must be met to ensure efficient and safe operation. Before selecting a cord, consult the manufacturer's guidelines for your equipment to determine its exact power needs. This includes looking into the voltage type (AC or DC) and the maximum current it draws during operation. Overlooking these details can result in insufficient power supply or, worse, electrical hazards.

Additionally, take into account the distance between your power source and equipment. The length of the cord can impact voltage drop, particularly for high-wattage devices. Using a cord that is too long or not rated for the required amperage can lead to overheating and reduced performance. Be sure to choose a cord that is not only compatible with your equipment in terms of power ratings but also suited for the environment it will be used in—whether indoor or outdoor. Selecting the correct equipment cord based on a thorough understanding of your power requirements ensures both safety and optimal functionality of your devices.

When selecting equipment cords, it's essential to understand the various types available and their specific applications. One common type is the power cord, which is crucial for supplying electricity to devices like computers, printers, and gaming consoles. Power cords come in different voltages and amperages, so it’s vital to choose one that matches the requirements of your equipment to ensure safety and functionality.

Another category is data cables, which are designed to facilitate the transmission of data between devices. Examples include USB cables for connecting peripherals to computers, as well as HDMI cables for delivering high-definition video and audio signals to displays. Networking cables, such as Ethernet cables, are also important for connecting computers and other devices to the internet, enabling seamless communication and data exchange.

Specialized cords are also available for particular applications, such as speaker wires for audio equipment or extension cords for providing additional reach. When choosing the right cord, consider the length, flexibility, and durability based on your specific needs and environment. Understanding these types and their uses will help you make an informed decision, ensuring that your equipment operates efficiently and safely.

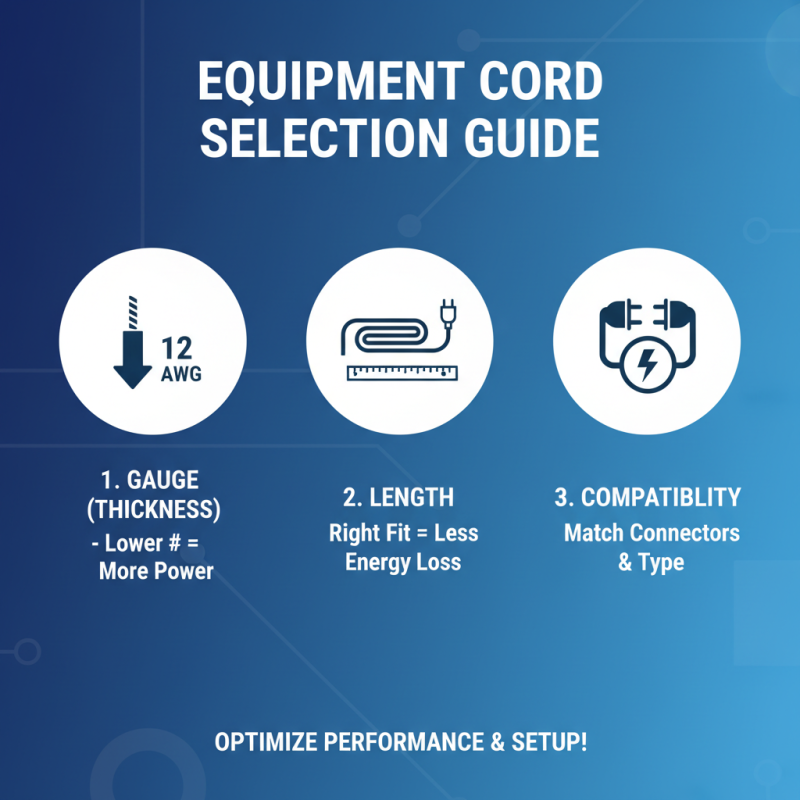

When selecting the best equipment cords for your needs, there are several key features to consider that can significantly impact performance and compatibility. Firstly, you should assess the cord’s gauge and length. A lower gauge number typically indicates a thicker wire, which allows for better current flow and is essential for heavy-duty applications. Additionally, the length of the cord should be appropriate for your setup, ensuring that it can reach your equipment without being excessively long, which can lead to energy loss.

Another important factor is the type of insulation used in the cord. Different materials offer varying levels of resistance to heat, moisture, and abrasion. For example, PVC insulation is common for general use, while rubber or silicone may be preferred for outdoor or high-heat environments. Always check whether the cord meets safety standards and is rated for the specific environment in which it will be used.

Tip: When purchasing cords, consider investing in products with strain relief features to minimize wear and tear at connection points. This investment can prolong the life of your cords, ultimately saving you money in the long run. Additionally, pay attention to the cord’s flexibility, especially if you need to maneuver it around corners or into tight spaces. A flexible cord will be easier to manage without risking damage.

When choosing equipment cords, understanding the material and durability is crucial to ensure they meet your specific needs. The most commonly used materials for cords are PVC, rubber, and thermoplastic elastomers (TPE). PVC cords are typically less expensive and provide good resistance to abrasion and moisture, making them suitable for indoor use. However, their rigidity can limit flexibility, especially in extreme temperatures. On the other hand, rubber cords offer superior flexibility and resistance to harsh weather conditions, making them ideal for outdoor applications. According to a report by the International Electrotechnical Commission, approximately 30% of equipment failures are attributed to cord damage, emphasizing the importance of selecting durable materials.

Moreover, durability doesn't solely depend on the material but also on the construction of the cords. Reinforced designs that include features like strain relief can significantly prolong the lifespan of cords by preventing fraying and breaking at the joints. A study published in the Journal of Electrical Engineering suggests that cords with higher tensile strength ratings—measured in pounds per square inch (psi)—show a correlation with reduced failure rates in real-world applications. Selecting cords that meet or exceed industry standards for strength and durability will not only enhance your equipment’s performance but also reduce any potential downtime caused by cord-related issues.

| Specification | Material | Durability (Years) | Heat Resistance (°C) | Flexibility Rating |

|---|---|---|---|---|

| Standard PVC | PVC | 3-5 | 70 | Moderate |

| Heavy-Duty Rubber | Rubber | 5-10 | 90 | High |

| Silicone Insulated | Silicone | 10-15 | 200 | Very High |

| Thermoplastic Elastomer (TPE) | TPE | 5-8 | 80 | High |

| Braid-Reinforced Cord | Braided Nylon | 8-12 | 100 | Very High |

When selecting equipment cords, understanding safety standards and regulations is crucial to ensure both performance and safety. Firstly, cords should comply with established international or local safety standards, such as UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission) regulations. These certifications indicate that the cords have been tested and meet specific safety criteria, reducing the risk of electrical hazards. Always check for labeling on cords that signifies such compliance to guarantee safety in your working environment.

In addition to certifications, it's essential to consider the application's requirements when choosing equipment cords. Different jobs may demand varying levels of durability, flexibility, and resistance to environmental factors like moisture or temperature changes. For instance, if the cords will be used outdoors or in industrial settings, opting for those rated for harsh conditions will ensure longevity and safety.

To further enhance safety, always inspect cords for any signs of wear or damage before use, and replace any faulty cords immediately. Avoid overloading cords beyond their specified capacity and ensure that they are properly grounded to prevent electrical shocks. Making informed choices based on these tips can significantly improve safety and performance in your application.