In the rapidly evolving field of electronics, circuit board equipment plays a crucial role in manufacturing precision components. The global market for circuit board production was valued at approximately $60 billion in 2022. It is projected to continue growing at a robust rate, driven by increased demand in consumer electronics, automotive applications, and medical devices.

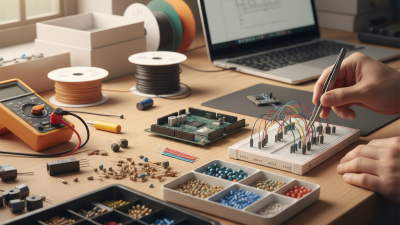

Manufacturers rely on advanced circuit board equipment to ensure high-quality products. This equipment includes PCB design software, soldering machines, and testing tools. However, many companies struggle with outdated machinery, leading to inefficiencies. Reports show that nearly 30% of manufacturers have not upgraded their equipment in over five years.

Investing in modern circuit board equipment can improve production speed and product reliability. Companies that innovate are more likely to succeed. Yet, the initial cost can be daunting. There is a pressing need for manufacturers to balance investment with the growing demand for electronic devices. Continuing to ignore circuit board equipment upgrades may hinder competitiveness in this dynamic market.

Circuit board equipment plays a crucial role in modern electronics manufacturing. It includes machines and tools that design, fabricate, and assemble circuit boards. These boards are the foundation for most electronic devices. Without proper equipment, manufacturers face challenges in producing reliable and efficient products.

Precision is key in the assembly process. Equipment must accurately position components on the boards. For instance, soldering machines must heat components just right. Too much heat can damage parts, while too little can lead to faulty connections. It's a delicate balance that requires constant monitoring.

Moreover, maintenance of circuit board equipment can be overlooked. Regular checks are essential to prevent downtimes. Sometimes, manufacturers find themselves using outdated tools. This can slow down production and impact quality. Staying updated with technological advancements is vital. Embracing modern techniques can enhance overall productivity, but it also demands investment and training.

Circuit board equipment plays a crucial role in electronics manufacturing. One key function is the production of circuit boards themselves. These boards serve as the foundation for electronic devices. Precise drilling and routing machines create pathways for electrical signals. The accuracy of these processes can greatly affect the final product’s reliability.

Another important function is the application of solder paste. Automated printers apply solder paste to specific areas of the board. This process requires exact placement. If misaligned, the components may not connect properly. Additionally, pick-and-place machines position components on the soldered pads. Ensuring these components fit accurately is critical. Errors can lead to product failures.

Testing is an essential aspect as well. As boards are assembled, they undergo various tests. These tests check for connectivity and functionality. If issues arise, manufacturing must address them promptly. Continuous improvement is essential in this stage. Reflecting on processes helps to eliminate recurring problems. The efficiency of circuit board equipment directly impacts overall production quality and speed.

In electronics manufacturing, various types of circuit board equipment play crucial roles.

Solder paste printers are essential for applying solder paste accurately. They ensure that components adhere firmly to the board. Inadequate application can lead to poor connections. This equipment operates with precision to minimize waste and improve efficiency.

Pick and place machines are also vital. They place components onto circuit boards quickly. However, misalignment can occur, resulting in defects. Regular calibration can address this issue but might require additional effort.

Reflow ovens are used to solder components securely. They heat boards to specific temperatures for optimal solder adhesion. Overheating can damage electronic parts, so monitoring is critical.

Another important device is the automated optical inspection (AOI) system. It inspects boards for defects post-assembly. This helps catch mistakes early, saving time and costs.

Though effective, AOI systems can sometimes miss subtle faults. Continuous improvement in these technologies is necessary. Ultimately, efficient use of circuit board equipment is vital for successful electronics manufacturing.

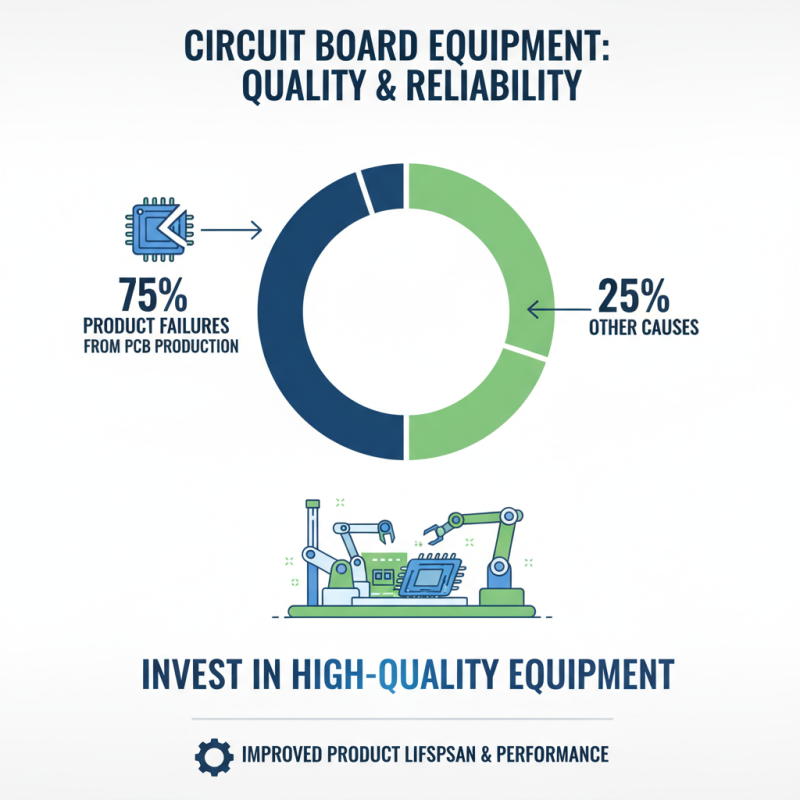

Circuit board equipment plays a crucial role in electronics manufacturing. Its influence on product quality and reliability is profound. According to a recent industry report, 75% of product failures can be traced back to issues in circuit board production. This statistic highlights the importance of investing in high-quality equipment.

Precision in circuit board fabrication is essential. High-quality machinery ensures accurate drilling, soldering, and etching. For instance, automated pick-and-place machines increase component placement accuracy to within ±0.01 mm. This level of precision significantly reduces defects. A small misalignment can lead to significant reliability issues. Furthermore, the choice of materials used in circuit boards also impacts overall product performance.

Despite advancements, challenges remain in managing equipment efficiency and maintenance. Regular calibration of machines is often overlooked, leading to potential quality issues. An alarming 30% of manufacturers reported equipment breakdowns due to poor maintenance. This can delay production cycles and increase costs. Electronic manufacturers must reflect on these practices. They need to prioritize not just the equipment but also the processes surrounding its upkeep to ensure product reliability.

The future of circuit board equipment is evolving rapidly. As electronic devices become more complex, manufacturers must keep pace. New technologies like automation and AI are changing production processes. This shift can increase efficiency but also poses challenges. Workers must adapt to new tools and methods. Training is essential, yet often overlooked.

Sustainability is another critical trend. Equipment that reduces waste will gain importance. The push for eco-friendly manufacturing is strong. Companies may face pressure to innovate or risk falling behind. However, transitioning to greener practices can be costly. Finding the right balance between cost and sustainability is difficult.

Additionally, the growth of IoT devices demands more from circuit board equipment. Designs must be smaller and more efficient. This can strain current capabilities. Many manufacturers struggle to keep up with these demands. It's a situation that warrants reconsideration of existing production strategies. As trends continue to shift, the industry must remain flexible. Adapting to these changes will be vital for future success.