In the realm of electrical applications, the role of equipment wire cannot be overstated. It serves as a crucial conduit for the transmission of electricity, ensuring safety and efficiency in various settings—from industrial machinery to residential systems. As highlighted by electrical engineer and industry expert Dr. Michael Thompson, "Without reliable equipment wire, the backbone of our electrical systems would be compromised.” This statement underscores the importance of selecting the right type of wire to meet specific electrical demands.

Understanding equipment wire involves recognizing its various specifications, including gauge, insulation type, and voltage rating. These characteristics are essential for determining its suitability for different applications, thereby impacting overall performance and safety. Additionally, the significance of equipment wire extends beyond mere functionality; it is integral in minimizing risks such as electrical fires and equipment malfunctions.

As we delve deeper into the subject, it becomes evident that the correct utilization of equipment wire is not just a technical requirement but a pivotal aspect of modern electrical engineering. Properly implemented, it safeguards systems and enhances their operational efficacy, ultimately reflecting the high standards of safety and performance that define the electrical industry today.

Equipment wire, also known as wiring for electrical equipment, plays a crucial role in various electrical applications due to its specific composition and design tailored for durability and efficiency. Typically made from copper or aluminum, equipment wire is insulated with materials that resist heat, moisture, and environmental pollutants. The National Electrical Manufacturers Association (NEMA) reports that approximately 70% of electrical failures can be attributed to improper wire selection, which underscores the need for understanding the composition of equipment wire.

The importance of equipment wire goes beyond basic electrical conduction; it also includes factors such as flexibility, weight, voltage rating, and resistance to chemicals and abrasions. According to the Institute of Electrical and Electronics Engineers (IEEE), choosing the right type of equipment wire can improve system reliability by up to 40%. This enhancement in reliability is particularly significant in sectors like manufacturing, where downtime due to electrical failures can cost companies thousands of dollars daily.

**Tip:** When selecting equipment wire, consider the specific application requirements, including temperature ratings and environmental conditions, to ensure optimal performance and longevity of electrical systems.

**Tip:** Regularly inspect wiring for wear or damage, as early detection can prevent costly repairs and enhance safety in electrical operations.

Equipment wire plays a crucial role in various electrical applications, enabling the safe and efficient transmission of electricity. Understanding the different types of equipment wire is essential for selecting the appropriate wire for specific tasks. Common types include THHN/THWN wire, which is versatile and suitable for general-purpose wiring in commercial and industrial settings. Another important type is MC (Metal Clad) cable, providing additional protection and preventing damage in harsh environments. Additionally, flexible cords are essential for portable equipment and can withstand movement and bending without compromising performance.

When choosing equipment wire, make sure to consider the wire gauge and insulation type to ensure it meets the required amperage ratings and environmental conditions. Tips for optimal performance include verifying compatibility with voltage levels and adhering to local electrical codes during installation. Always ensure that the wire's temperature rating is suitable for the intended application, especially in high-heat environments where overheating could pose a safety risk.

It's also important to remember that proper wire management, including securing cables and avoiding tight bends, can enhance longevity and performance. Regular inspections can help identify potential wear and tear, allowing for timely replacements before issues arise.

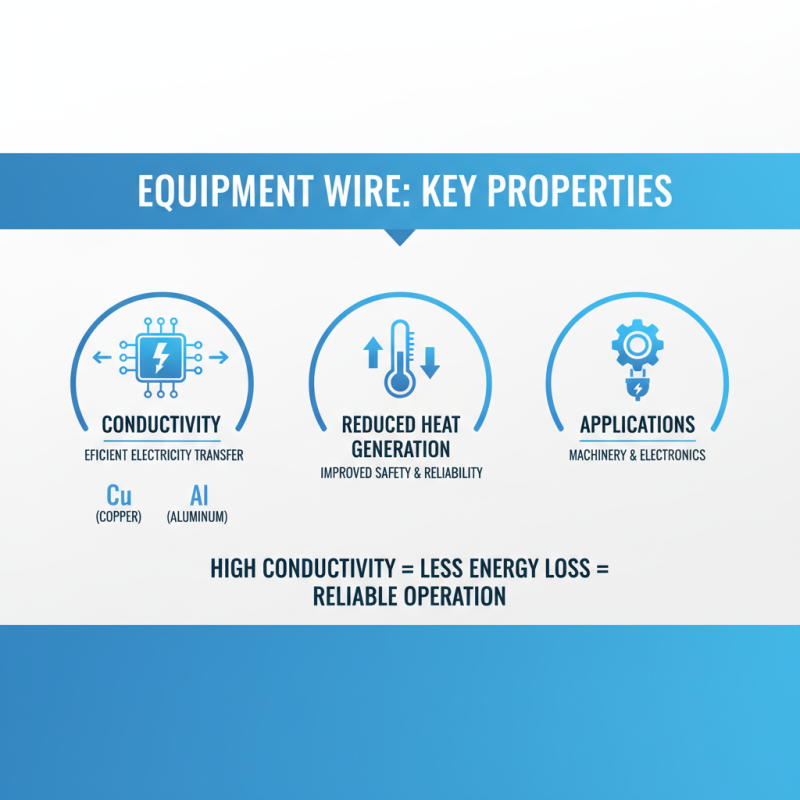

Equipment wire is a crucial component in various electrical applications, and its key properties and characteristics significantly influence performance and safety. One of the main attributes of equipment wire is its conductivity, which allows for efficient electricity transfer. The materials used in crafting the wire, such as copper or aluminum, determine its ability to conduct electrical current. High conductivity reduces energy loss and minimizes heat generation, making it essential for reliable operation in machinery and electronic devices.

Another important characteristic is the insulation used around the wire. Proper insulation materials protect against electrical leakage and short circuits, ensuring safety during operation. Different applications may require specific insulation types that can withstand varying temperatures, chemical exposure, or physical abrasion. Flexibility is also vital, as equipment wires must navigate through tight spaces and conform to different configurations without compromising performance. Overall, understanding these properties helps engineers and technicians select the appropriate equipment wire for their specific electrical needs, enhancing functionality and safety in their applications.

Equipment wire plays a crucial role in ensuring both safety and performance in various electrical applications. According to a report by the National Fire Protection Association (NFPA), electrical failures are a leading cause of residential fires, underscoring the importance of using high-quality wiring materials that comply with stringent safety standards. Equipment wire, specifically designed for electrical systems, provides the necessary insulation and conductivity to minimize short circuits and overheating. The choice of appropriate wire gauge and type not only enhances the system's reliability but also safeguards against potential hazards.

In industrial settings, the significance of equipment wire extends to operational efficiency and equipment longevity. The International Electrotechnical Commission (IEC) emphasizes that properly rated wiring can reduce energy losses and improve the overall performance of electrical installations. A study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that the use of suitable equipment wire can increase the lifespan of electrical components by 30%, thus delivering substantial cost savings over time. By ensuring that equipment wire is selected based on the specific requirements of the application, businesses can enhance productivity while adhering to safety regulations, ultimately supporting the longevity and safety of electrical systems in every environment.

This chart illustrates the importance level of various types of equipment wire used in electrical applications, with a scale from 1 to 10, highlighting their significance in ensuring safety and performance in electrical systems.

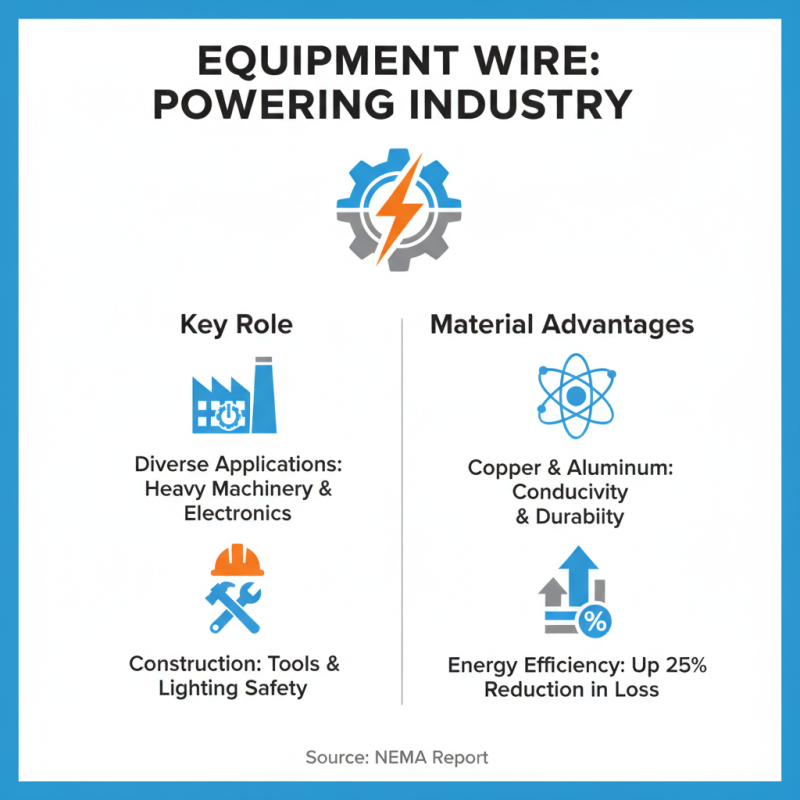

Equipment wire plays a crucial role in various industries, powering applications that range from heavy machinery to intricate electronic devices. In the construction industry, for instance, the National Electrical Manufacturers Association (NEMA) reports that equipment wire is essential for the safe and efficient operation of tools and lighting systems. The use of copper and aluminum wires helps reduce energy loss, enhancing operational efficiency by up to 25%. These materials are favored for their conductivity and durability, which are vital in environments that face extreme temperatures or physical stress.

In the automotive sector, equipment wire is integral for the functionality of electrical systems, including lighting, infotainment, and safety features. According to a report by MarketsandMarkets, the global automotive wire and cable market is projected to reach USD 36 billion by 2026, driven by the increasing demand for advanced automotive technology and electric vehicles. This surge highlights the importance of specialized equipment wires designed to withstand vibrations, heat, and moisture, ensuring reliability and longevity even in the most demanding conditions. The adoption of high-performance wiring solutions contributes significantly to the industry's ability to meet stringent safety and efficiency standards.